SPS: Why is graphite so hard?

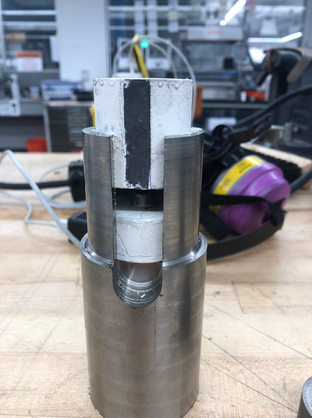

As I've explained earlier, SPS works by applying a lot of physical pressure and heat to a material under high vacuum environment. The pressure and heat aspects of this system of designed in a very smart way to be supplied by the same source, which is the punch and die system. Made by graphite, the punch is conductive, thus any material put between two punches can be heat up by running a pulsed DC current through the punches and the material. Also having a very high compressive strength, graphite becomes an almost perfect material to use to apply pressure as well.

So we use boron nitride spray, which is an electrically insulating material, to coat the graphite pieces, which then go connect to electric feedthroughs inside of the vacuum. Boron nitride gives us control over what should conduct and what shouldn't. However, turns out both these materials are not really the miraculous choices we though them to be. Boron nitride, being in spray form leads to a lot of off gassing in vacuum environment which slows down the vacuum pull, and also can easily scrape off to expose the conductive graphite. Graphite on the other hand, at least what was available to us, wasn't able to withstand pressures larger than 50MPa, when the SPS needs and order of 100s of MPa.

As solutions, we've tried using paste formed boron nitride, alumina powder, and alumina fibers and ran into similar problem. The solutions we're considering now are preloading the graphite with boron nitride coated carbon fiber, so we address the issue of compressive strength as well as the powder insulator scraping off, or we replace the punch and the die with a less conductive but stronger metal.

This project is still in progress...